Faculty of Chemistry and Chemical Technology, University of Ljubljana

Microprocess Engineering Research Group

We are a research-focused department at the Faculty of Chemistry and Chemical Technology, University of Ljubljana. Our team works on cutting-edge chemical engineering challenges, from sustainable processes to advanced materials and reaction engineering. We combine experiments and simulations to tackle real-world environmental and industrial problems. Collaboration and innovation drive everything we do, making our research impactful and globally relevant.

Wha are we doing?

Field of research

Latest Invited Lectures

View allI. Plazl

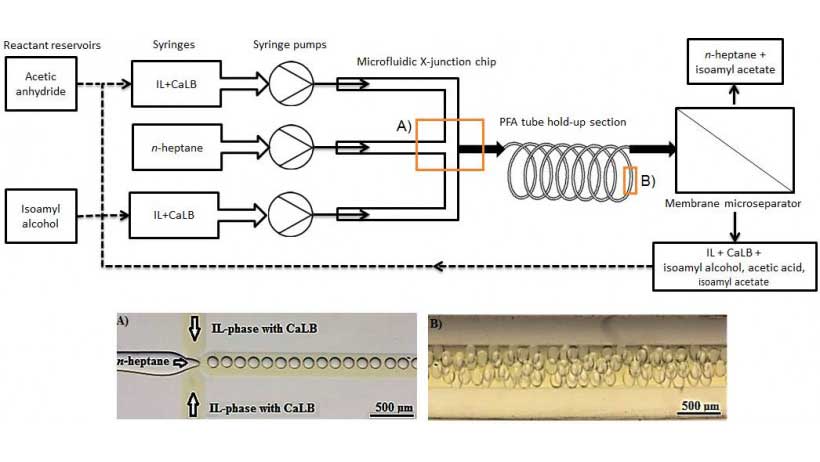

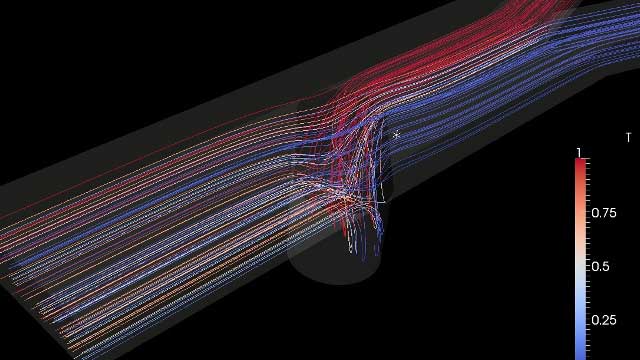

Modeling and Design of Biocatalytic Processes in Parallel-Plate Microbioreactors. European Society of Applied Biocatalysis – ESAB Webinar on Biocatalytic Process Engineering

P. Žnidaršič Plazl

Biocatalysis in Microflow Systems

P. Žnidaršič Plazl

Immobilized biocatalysts in miniaturized flow systems (keynote lecture). The 14th International Conference on Protein Stabilization 2025: ProtStab 2025.

Latest Publications

View allT. A. Gazis, J. Wuyts, A. Moutsiou, G. Volpin, M. J. Ford, R. I. Teixeira, K.M. P. Wheelhouse, P. Natho, P. Žnidaršič-Plazl, S. Jost, R. Luisi, B. Benyahia, B. U. W. Maes, G. Vile. Towards greener-by-design fine chemicals. Part 1: synthetic frontiers. Chem. Soc. Rev. 2026, 55, 619-674

D. Yordanova Apostolova, I. Bardarov, A. Ø. Tjell, E. Gričar, M. Starin, P. Farinazzo Bergamo Dias Martins, M. Nosan, T. Mayr, D. Strmčnik, I. Plazl, B. Genorio. A parallel-plate electrochemical microreactor for the continuous production of hydrogen peroxide. Chem. Eng. J. 2025, 525, 170301

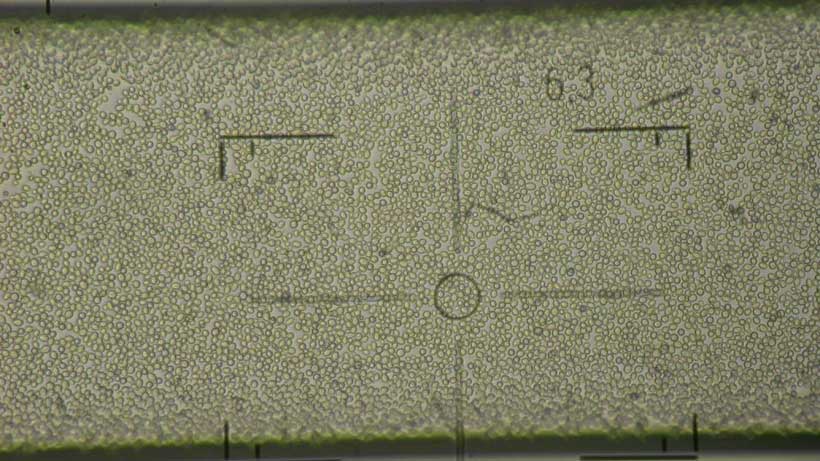

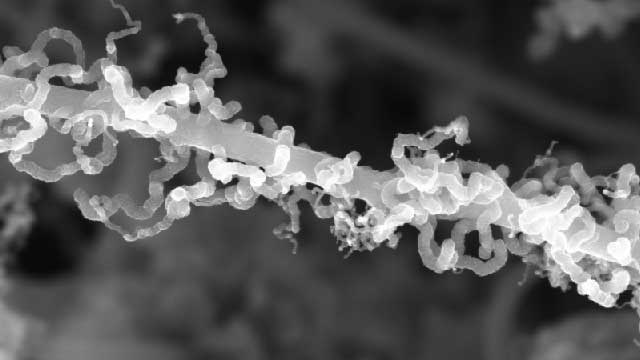

T. Menegatti, Ž. Lavrič, P. Hlebanja, P. Žnidaršič-Plazl. Microfluidics-based generation and immobilization of nanoscale cross-linked enzyme aggregates for continuous transamination. Chem. Eng. J. 2025, 523, 168865168865.

Latest Awards

View allPrešeren Award for Students (Faculty of Chemistry and Chemical Technology, University of Ljubljana) for the Master thesis: “Design and application of a microstructured pervaporation device for selective separation of model molecules from water”; Supervisor: Doc. Dr. Rok Ambrožič

Prešeren Award for Students (Faculty of Chemistry and Chemical Technology, University of Ljubljana) for the Master thesis: “Immobilization of glucose oxidase into cross-linked enzyme aggregates using microfluidic system”; Supervisor: Prof. Dr. Polona Žnidaršič Plazl, 2025

Zois award for outstanding achievements in the field of chemical and biochemical microprocess engineering (Republic of Slovenia)