Biotransformations

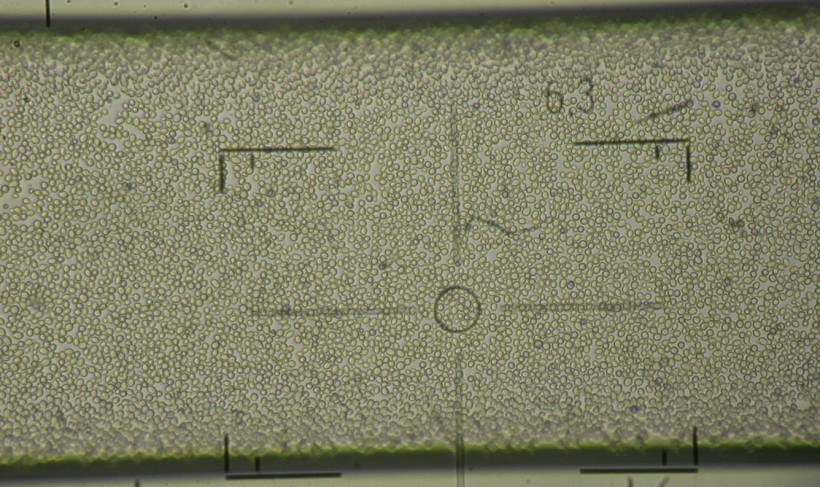

Microbioreactors with enzymes and whole cells as catalysts were developed for further biotransformations with immobilized or free biocatalysts. Enzymes were immobilized either by surface silanization and covalent linkage with glutaraldehyde [Stojkovič et al., 2011] or by retention of commercially available enzymes attached to microporous spheres. The latter approach was used to develop a packed-bed reactor for production of various esters [Pohar et al., 2012; Cvjetko et al., 2012].

Furthermore, surface immobilization of procaryotic as well as eucaryotic cells on various materials was studied [Stojkovič et al., 2010, Stojkovič et al., 2014]. Whole-cell biotransformations performed in continuously operated miniaturized systems also confirmed to be attractive alternatives for the process development studies or for the synthesis of industrially relevant compounds. Continuous production of widely used acidulant L-malic acid from fumaric acid using permeabilized Saccharomyces cerevisiae cells within polymeric microchannel system revealed four times higher specific volumetric productivity than reported for the bench-scale membrane reactor with immobilized yeast cells. [Stojkovič and Žnidaršič-Plazl, 2012].

Studies considering enzymatic reactions with dissolved enzymes encompass lipase B-catalyzed isoamyl acetate synthesis [Pohar et al., 2009; Novak and Žnidaršič Plazl, 2013] and cholesterol oxidation [Marques et al., 2010; Marques et al., 2012] in a two-liquid phase system, as well as laccase-catalyzed L-DOPA oxidation in a homogeneous system [Tišma et al., 2009].